In the world of modern copper electrowinning and electrorefining, the permanent stainless steel cathode plate has become the industry standard, replacing the labor-intensive starter sheet process. While the quality of the stainless steel blade is critical, the design of the hanger bar (conductive beam) is equally vital for ensuring optimal electrical conductivity, mechanical strength, and long-term durability in the harsh tankhouse environment.

Choosing the right hanger bar is a key decision that impacts your plant’s energy efficiency, maintenance costs, and productivity. In this article, we break down the three primary hanger bar technologies we offer, explaining the advantages and ideal applications of each to help you make an informed choice.

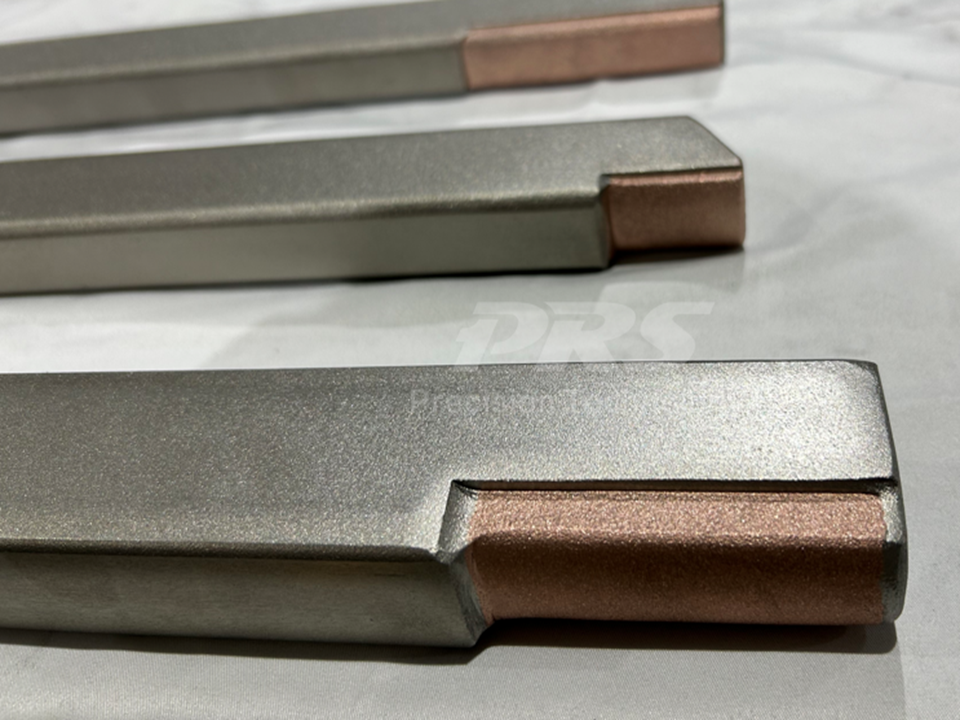

1. Stainless Steel Cladding Copper (The KIDD Process Hanger Bar)

This design represents a high-performance approach focused on maximum longevity and corrosion protection.

Construction: A solid copper core is fully and permanently encapsulated within a sheath made of 316L stainless steel . The assembly is completed by welding the stainless steel cathode blade to the stainless steel cladding of the hanger bar, typically using an automated robotic laser welding process for a perfect joint.

Key Advantages:

- Superior Corrosion Resistance: The stainless steel sheath provides a complete barrier, protecting the conductive copper core from acidic mist and corrosion throughout its lifespan.

- Excellent Mechanical Integrity: The robust construction makes it highly resistant to physical damage during handling and automated stripping.

- Long Service Life: This design is engineered for maximum durability, making it a cost-effective solution over the long term despite a higher initial investment.

Best For: Operations in highly corrosive environments or those prioritizing minimal maintenance and maximum operational uptime.

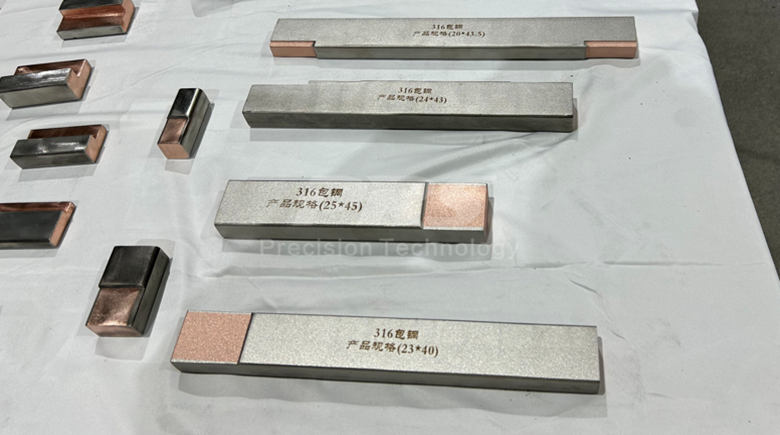

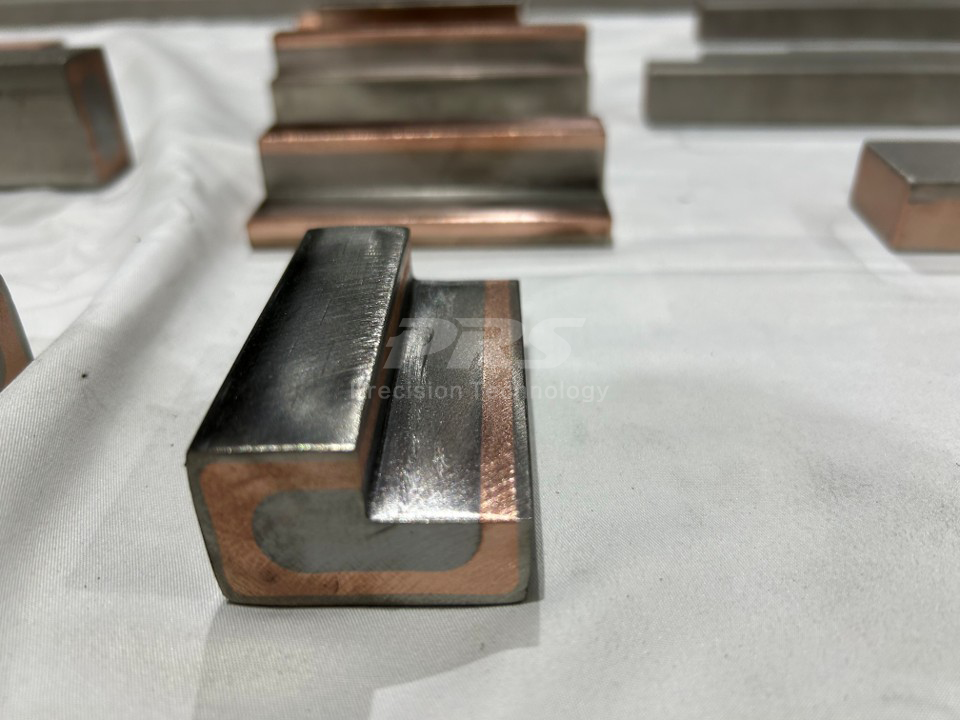

2. Copper Cladding Stainless Steel (The ISA Process Hanger Bar)

This is a widely adopted, cost-effective design that prioritizes excellent conductivity and proven performance.

Construction: This design inverts the materials: a core of 304 stainless steel is clad with a layer of high-conductivity copper (ASTM C11000). For the welding process, three longitudinal slots are machined into the bottom of the copper cladding to expose the underlying stainless steel core. The cathode blade is then welded to this exposed core using manual acetylene welding.

Key Advantages:

- Proven and Reliable: A well-understood and widely used technology, offering a reliable and effective solution.

- Cost-Effective: Generally offers a lower initial procurement cost compared to the fully stainless cladding copper option.

- Good Conductivity: Provides the excellent electrical conductivity of copper directly at the connection points.

Best For: Standard electrowinning and electrorefining conditions where a proven, economical solution is required.

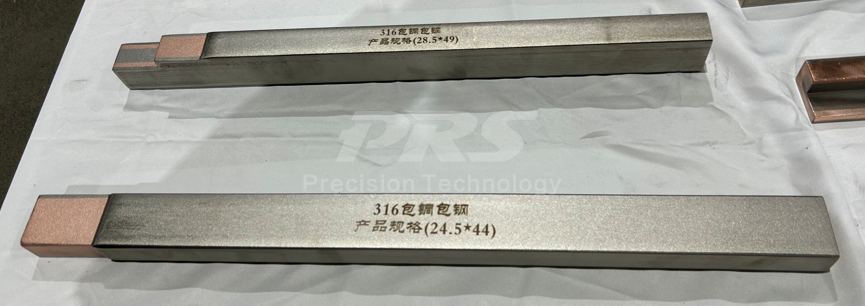

3. Stainless Steel Cladding Copper Cladding Mild Steel (The Optimized Copper-saving Design)

This innovative design combines the best features of the first two, offering a superior balance of performance, cost, and durability.

Construction: This triple-layer hybrid features a mild steel core for structural strength, a middle layer of copper for optimal conductivity, and an outer cladding of 316L stainless steel for corrosion protection. The cathode blade is welded to the stainless steel outer layer by automatic laser welding process.

Key Advantages:

- Optimized Cost: By reducing the amount of copper used and incorporating a steel core, this design offers a more attractive price point than the full stainless cladding copper hanger bar without sacrificing key performance features.

- Maintained Corrosion Protection: The outer 316L stainless steel layer still shields the internal metals from corrosion, ensuring a long service life.

- Excellent Conductivity: Verified to perform efficiently at industry-standard current densities up to 660 A/m².

Best For: Plants seeking the ideal balance between the longevity of the KIDD-style bar and the cost-effectiveness of the ISA-style bar. It is an excellent value-engineered solution.

Comparison Table: Hanger Bar (Conductive Beam) Technologies at a Glance

| Feature | Stainless Steel Cladding Copper (KIDD Process) | Copper Cladding Stainless Steel (ISA Process) | Stainless Cladding Copper Cladding Steel (Improved Copper-saving Design) |

| Core Construction | Copper core, 316L stainless steel jacket | 304 stainless steel core, copper cladding | Steel core, copper layer, 316L stainless steel sheath |

| Key Advantage | Maximum corrosion resistance & lifespan | Proven technology & cost-effectiveness | Optimal balance of cost and performance |

| Corrosion Protection | Excellent (full barrier) | Good (copper is exposed) | Excellent (full barrier) |

| Relative Cost | Higher | Lower | Medium (Best Value) |

| Welding Method | Automated Robotic Laser Welding | Manual Acetylene Welding | Automated Robotic Laser Welding |

| Ideal Application | Highly corrosive environments; maximum uptime | Standard conditions; budget-conscious projects | Balanced performance for most operations |

Making the Right Choice for Your Operation

There is no single “best” hanger bar for every situation. The optimal choice depends on your specific operational priorities:

- Choose Stainless Steel Cladding Copper for the highest level of corrosion protection and the longest possible service life, especially in demanding environments.

- Choose Copper Cladding Stainless Steel for a reliable, proven, and cost-effective solution for standard tankhouse conditions.

- Choose the Stainless Steel Cladding Copper Cladding Steel for the best overall value, balancing excellent performance with a reduced initial investment.

We are here to help you decide. Our technical experts can assess your plant’s specific conditions—including electrolyte chemistry, current density, and operational goals—to recommend the perfect hanger bar (conductive beam) design for your needs.

Contact us today to discuss your requirements and request a quotation. Let us provide you with a cathode solution that ensures maximum efficiency and profitability for your tankhouse.