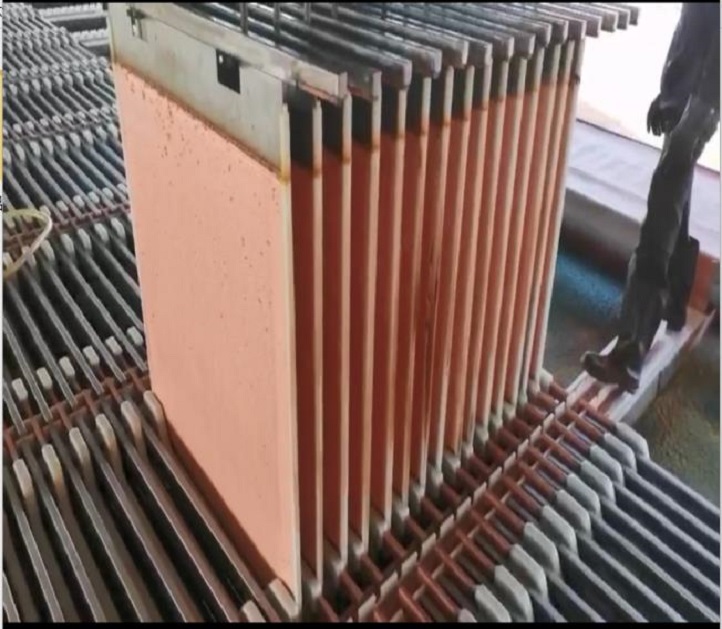

Lead Alloy Anode Plate for Copper Electrowinning

1. The plate surface is flat, and the alloy composition is evenly distributed.

2. Embossing was added as a surface treatment process, which enhances the corrosion resistance of the anode plates while reducing the lead content in the cathode copper.

3. Holes are on the plate which makes that the electrolyte has good fluidity.