In the demanding environment of a copper electrowinning plant, every component must deliver maximum reliability and efficiency. The stainless steel cathode, while seemingly simple, is a cornerstone of productivity. Its design directly impacts operational costs, production quality, and maintenance schedules.

At PRS, we engineer cathodes for longevity and peak performance. Based on our extensive experience, here are the five critical design details that separate a standard cathode from a superior one.

1. Selecting the Right Stainless Steel Grade for Cathode: A Strategic Choice

The choice of stainless steel is the foundation of cathode performance. There is no one-size-fits-all solution; the optimal grade depends on your project’s specific conditions and scale.

- For Challenging Conditions & Tighter Budgets: If your operation is smaller (e.g., under 5,000 TPA), involves manual stripping, or faces highly corrosive electrolytes (e.g., with high chloride ion concentration), we recommend LDX 2101. This cost-effective, nickel-saving duplex stainless steel offers exceptional resistance to chloride stress corrosion cracking and higher structural strength.

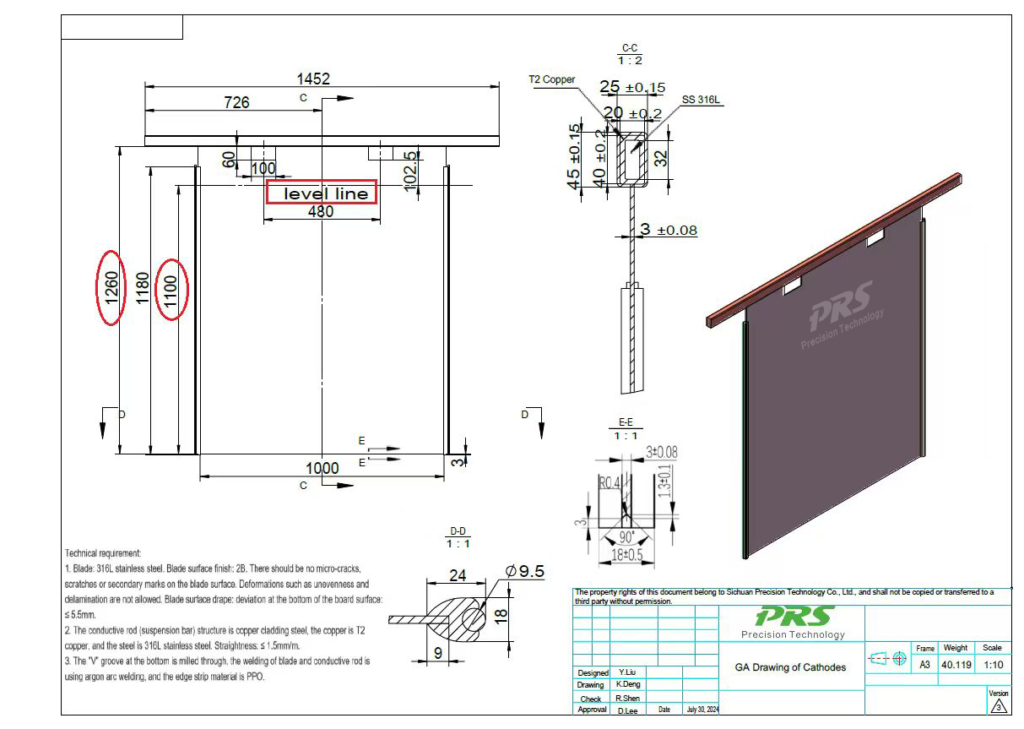

- For Large-Scale, Automated Plants: For larger operations (over 5,000 TPA) with favorable conditions that use automated cathode stripping machines, 316L stainless steel is the preferred choice. It can achieve a smooth 2B surface finish, ensuring consistent, high-quality stripping cycle after cycle.

We help our clients navigate this critical first decision by assessing their unique operational needs.

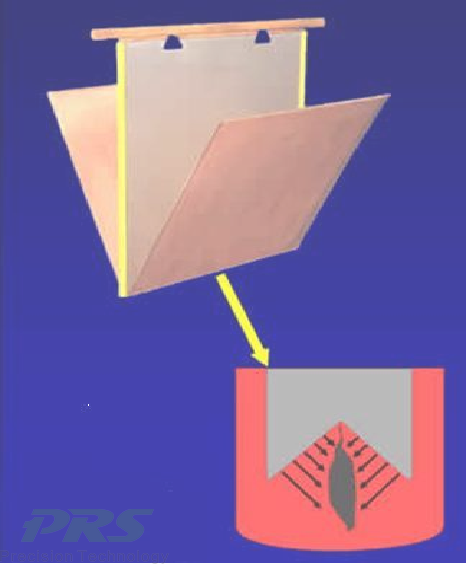

2. The V-Shaped Groove at the Bottom: Eliminating the Need for Wax Coating

Traditionally, operators applied wax to the bottom of cathode blades to prevent deposited copper from sticking, a process that required reapplication after every cycle.

Our design incorporates a milled V-shaped groove at the bottom of the blade. This simple yet effective innovation eliminates the need for wax entirely. The groove creates a natural break point, allowing the copper sheet to be cleanly and easily stripped every time. This one-time modification delivers continuous benefits: it reduces operational costs, removes the need for waxing devices, and increases overall production efficiency.

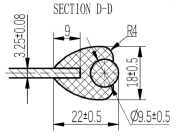

3. Tension Rods in Edge Strips: Enhanced Durability and Corrosion Resistance

The edges of the cathode blade are particularly vulnerable to wear and corrosion. To combat this, our edge strips are secured using an integrated tension rod system.

The blade edge is inserted into the strip’s groove, and a tension rod is placed into the circular groove on the strip’s outer side. This rod acts on a lever principle, pulling the strip tightly and securely around the blade. This robust design significantly improves corrosion resistance at the edges, extends the cathode’s service life, and minimizes wear-related downtime, reducing your long-term spare parts costs.

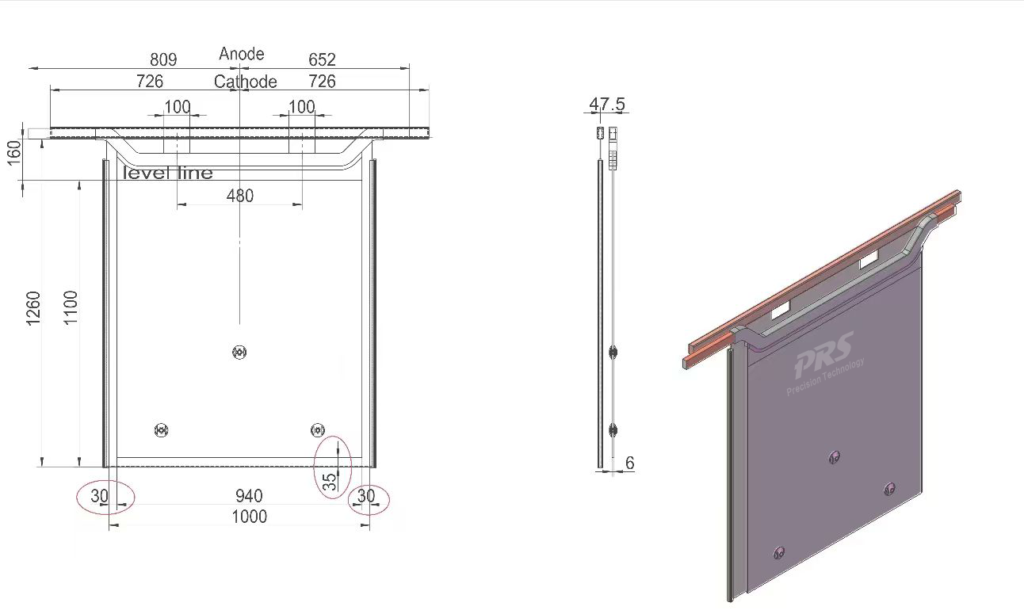

4. Larger Cathode Blade Dimensions Than Anode Blade: For a Uniform Copper Sheet

To produce a high-quality cathode copper sheet with a consistent thickness, the cathode blade must be larger than the anode. In our design, the cathode deposition area is typically 30mm wider and 35-40mm taller than the anode blade.

This intentional size difference prevents the formation of thick, uneven edges and bottom sections on the deposited copper sheet. The result is a more uniform deposition that is easier and faster to strip, preventing operational delays and damage during the harvesting process.

5. Optimal Distance from Liquid Level to Weld: Protecting a Critical Junction

The weld where the conductive beam meets the blade is a critical point vulnerable to acid mist corrosion. To ensure its protection, the distance between this weld and the electrolyte’s liquid level line must be carefully controlled.

We design this distance to be 150mm ± 50mm. This range accounts for normal liquid level fluctuations and ensures the weld remains safely above the corrosive environment. This protection is fundamental to maximizing the cathode’s lifespan, which can extend up to 15 years in well-maintained operations.

Engineered for Long-Term Value

These five design principles—material selection, the V-shaped groove, the tension rod system, optimized blade dimensions, and protected weld points—are integrated into every cathode we produce. They share a single goal: to enhance your plant’s performance, efficiency, and profitability by delivering a cathode built to last.

By focusing on these critical details, we ensure our stainless steel cathodes provide unparalleled reliability and become a long-term, cost-effective asset for your electrowinning operation.

Ready to optimize your cathode performance? Contact us to discuss the best cathode solution for your specific plant conditions.