Considering an upgrade from traditional starter sheets to permanent stainless steel cathodes? We analyze efficiency, cost, and ROI to help you decide and show how our engineering ensures a successful transition.

In today’s competitive copper electrorefining landscape, maximizing operational efficiency is essential. While starter sheets long served as the industry norm, permanent stainless steel cathode technology has redefined performance benchmarks. If you’re planning an upgrade or designing a new refinery, understanding the tangible differences between these methods is crucial. This article offers a clear, data-informed comparison to support your decision-making.

Head-to-Head: Where Modern Cathode Technology Excels

Though both processes produce high-purity cathode copper, their operational frameworks and economic outcomes differ considerably.

1. Operational Workflow & Labor Requirements

- Permanent Cathode Process: Streamlined by design. Reusable stainless steel blanks are stripped automatically and returned directly to cells, eliminating several manual steps.

- Starter Sheet Process: Requires a separate plating circuit to produce delicate copper starter sheets, involving manual handling, pressing, and looping—a labor-heavy and complex workflow.

The Data: Facilities using permanent cathodes can reduce tank house staffing by 40–50% compared to starter sheet operations. This shift not only cuts labor costs but also improves workplace safety through automation.

2. Productivity & Operational Stability

- Permanent Cathode Process: The rigidity and flatness of stainless steel blanks enable two key benefits:

- Higher Sustainable Current Densities: Operation at 300–330 A/m² or more is achievable.

- Tighter Electrode Spacing: Minimal gaps (~95–100 mm) help maximize amperage efficiency.

- Starter Sheet Process: Soft, flexible starter sheets are prone to warping, which limits performance:

- Typical current densities cap at 220–260 A/m².

- Wider spacing (>110 mm) is needed to avoid short-circuiting.

The Data: By combining higher current with closer spacing, permanent cathode technology can boost production capacity by 15–25% within the same floor area.

3. Output Quality & Metal Efficiency

- Permanent Cathode Process: Automated harvesting yields uniform, high-density cathodes with minimal residue. Mechanical stripping preserves cathode integrity.

- Starter Sheet Process: Manual handling introduces variability, and higher anode stub residuals are common to aid processing.

The Data: Permanent cathode systems often achieve residue rates below 15%, compared to 18–22% with starter sheets—translating to more saleable copper per cycle.

4. Financial Perspective: CAPEX vs. OPEX

It’s true that permanent cathode technology involves higher initial capital investment—roughly 10–20% more for tank house equipment. Starter sheets may appear attractive due to lower upfront costs. However, a full cost-of-ownership view reveals a different story. Permanent cathodes deliver ongoing operational savings that typically yield a rapid return:

- Reduced labor and energy use per ton of copper

- Less metal tied up as work-in-process

- Smaller physical footprint, lowering building costs

Conclusion: Most modern copper refineries see a strong ROI with payback periods of just a few years, thanks to sustained OPEX reductions.

The Clear Choice for Future-Focused Refineries

While starter sheet technology is reliable, permanent stainless steel cathodes offer undeniable gains in efficiency, cost control, and productivity. They are the standard for new world-class copper electrorefining facilities. The central question is no longer whether to upgrade—but how to implement it successfully.

A smooth and effective transition depends on precise engineering and integration. Poor design can undermine even the best technology.

How We Help You Maximize ROI

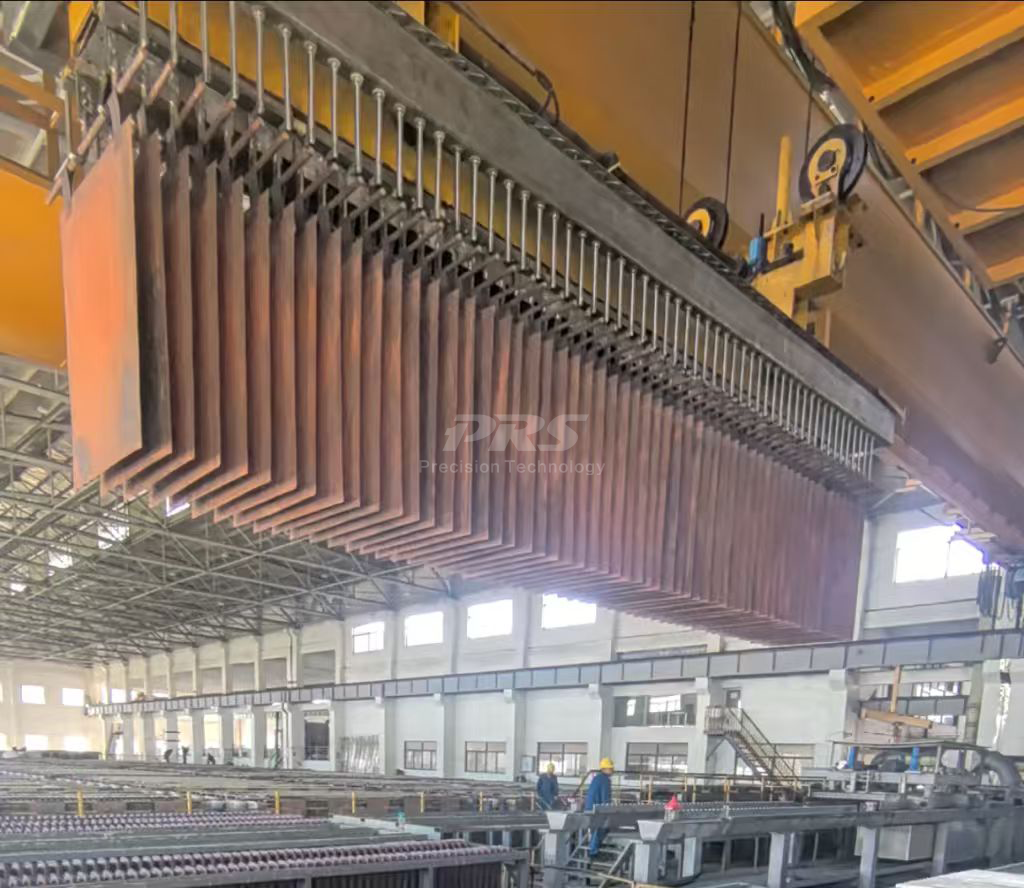

At PRS, we specialize in designing and commissioning high-performance cathode systems. We focus on delivering measurable returns through:

- Optimized Cell & Busbar Layout: Ensuring even current distribution and energy efficiency.

- Seamless Material Handling Integration: Engineering fully automated stripping and transport systems for maximum uptime.

- Precision Electrode Alignment: Enabling minimal electrodes spacing to unlock full productivity gains.

We provide the engineering rigor that turns advanced technology into lasting operational advantage.

Ready to Boost Your Refinery’s Performance?

If you’re looking to enhance productivity, reduce operating costs, and drive profitability, our team brings proven expertise in designing and modernizing cathode systems for the global copper industry.

Contact us today for a confidential consultation. Let’s explore how our engineering support can help you build a more efficient and profitable operation.